Cue Build for Booth

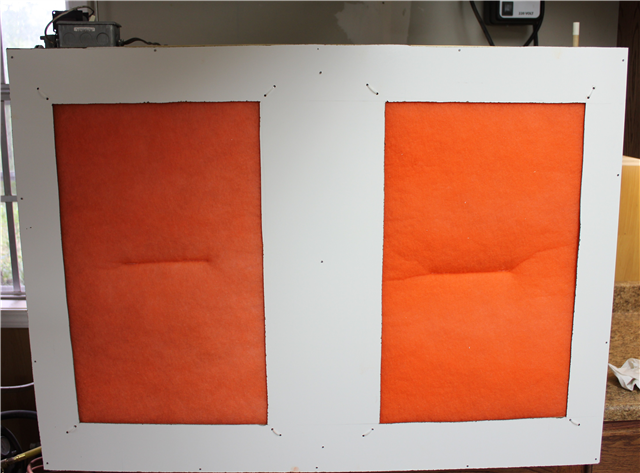

Pic of cover. The two filters shown (high quality dense filters specifically for spray applications) are essentially dust filters. They are secured on the inside of the cover by zip ties at the corners.

The few orange smudges are from the filters as they are tacky. Wiped off with some alcohol. Saw cuts arent exactly clean. The cover is a wainscott board (was already white).

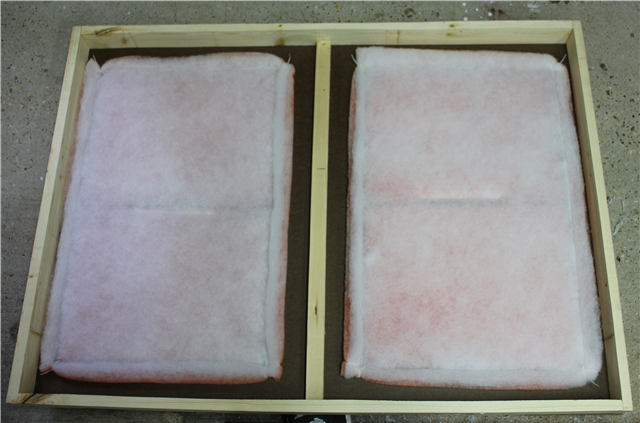

Pic of the inside of the cover. The filters have a wire frame on the inside. I may paint or stain the frame to match the rest booth...or I might decide enough is enough.

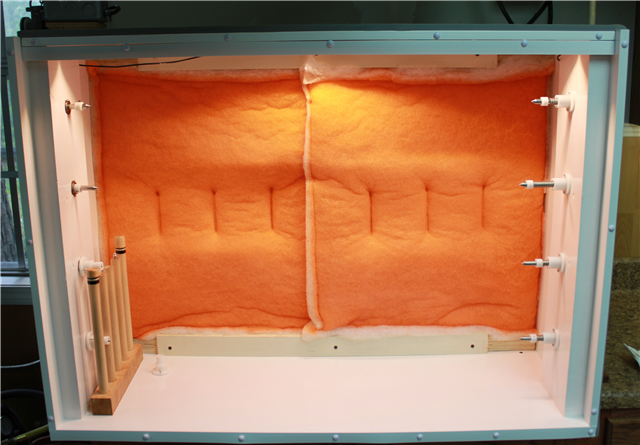

Pic of the booth with cover removed. The two thick up rights are original to the finsh lathe. The original top and bottom of the frame were discarded.

There is a 3 deep plenum between the back of the filters and the back of the booth in order to distribute the air flow. Some strips of wood forming a channel hold the filters (that wire frame again) firmly in place.

Pic of left side. All of the hardware and pulleys are original. This pic shows how far past the counter edge the booth hangs. Unfortunate, but not a problem. It isnt a major walking area, and there is plenty of room in the front of the booth.

Note the spinner setup has its own switch up top.

Pic of right side. The exhaust, lights, and spinner can be turned on/off via the power strip mounted to the booth. The shaft rack mounted to the booth should be very convenient.

The foam insulation is for a close fit when intalling the cover. It doesnt have to be air tight, but I wanted to reduce the air flow into the booth not through the filters at least some. I may have to tweak the insulation design.

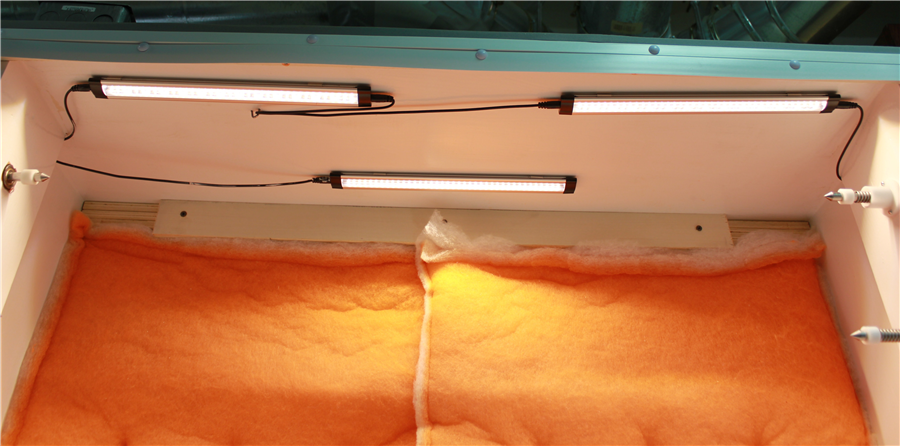

Pic of lights. I see the one on the right is crooked. I will fix that as I have the two front lights slightly in front of the centers to help reduce shading.

I found the biggest hassle with the spray lathe was trying to keep the bearings clean. I decide to make some shields this time around. For the drive side, the delrin stops are permanently placed so the shield extends all the way out to the center.

For the support side, I extended it far enough to keep the bearings clean but still give me access to the stop and springs for varying cue/shaft lengths.

I had to make two adapters, one to go between the motor and the back of the booth, and one to fit around the rectangular exhaust port. After a fair amount of deliberation, I decide to go with a closet flange and 4 inch DWV PVC.

The pipe going through the wall didnt go very far into the elbow (note all of the exposde primer), but far enough. There isnt any real pressure on these anyway, just exhaust. There is another elbow just on the other side of the wall outside with a pipe attached to it pointing at the ground.

I made a black collar from phenolic sheet to hide the terrible job of cutting holes in the wall for the pipe.

There is a spot or two where I can just feel some air around the rectangular fitting. Im hoping a few more dabs of caulk might eliminate it, but since I will still be wearing my respirator Im not concerned.

It will be nice to stand in one place and put on mask, mix clear, shoot cues, clean gun, hang gun, put on cover, take off mask, and walk out.